February 8, 2022 : 2 min read

The Current State of the X-Ray Tube Supply Chain

The X-ray tube market is not immune to the supply chain "pinch" being felt in almost every other industry right now. But how dramatic is the pinch? What's causing it? And how are vendors that sell tubes responding? To answer those questions, we'll share our take on what buyers can expect from the X-ray tube market in the next year.

How will the availability of X-ray tubes change?

Over the next 9-12 months, end users can expect to see the availability of new OEM tubes decline to levels that may make finding replacements a challenge, even for very common models. With these challenges in effect, demand is likely to increase for third-party options, including after-market, used, and repaired tubes. This will, in turn, tighten supply slightly in this segment of the market too.

What's causing the shift in availability?

There are two primary factors that will see tube availability decreasing:

1. Back orders for new X-ray equipment are occupying OEMs' tube manufacturing capacity. Essentially, whenever a tube is made, it's going directly into a new system that has already been sold. Under normal circumstances, some of these tubes would go onto the shelves of parts warehouses to be sold as replacements.

2. Disruptions in the supply chains of sub-components are slowing production of new tubes. Because X-ray tubes are used in medical devices, each piece of them is subject to regulatory scrutiny. If even the most basic piece of a tube is on back order, it's not a quick or easy feat for a manufacturer to implement a substitute that meets regulatory approval.

With both of these factors in play, anyone looking for a brand-new, OEM tube will likely either be forced to wait, or to look into the options offered by third parties.

What can be done?

While some of what you've read so far suggests challenges in the near future, we believe there will still be high-quality options for end users who find themselves needing to replace an X-ray tube in the next year. These options will, largely, come from the strengths of third-party organizations, including:

1. Used tubes. The third-party parts market has a strong supply of used tubes. If you purchase a used tube from a quality parts provider, it will be tested and validated for functionality and, in some cases, even covered by a limited warranty. It will also be priced significantly lower than a new tube.

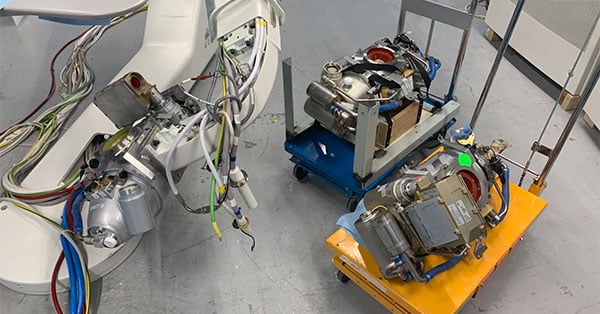

2. More tube reprocessing. Block Imaging is expanding our capabilities to increase the supply of reprocessed tubes. Tubes like these are not only tested and validated, they are also put through processes that correct arcing, air bubbles, or impurities that can damage a tube over time. These processes extend the overall lifespan of the tube. A reprocessed tube will typically last somewhere between a used tube and a new tube and are priced accordingly.

The Takeaway

Much like the last 24 months, the next 9-12 will not be what we are used to in the medical imaging equipment industry. With that said, facilities that have traditionally relied on new OEM parts may need to turn to solutions they are not used to. Fortunately, recent growth and expansion among third-party providers like Block Imaging is helping to make sure those solutions come through with both quality and savings, in spite of current challenges.

Whether you need an X-ray tube now, or are simply being proactive about lining up your next replacement, our team is ready to help with tubes for all manufacturers and modalities. Use the button below to tell us how we can help!

Jason Crawford

Jason Crawford is the President of Block Imaging. Jason’s biggest interests involve anything that brings new insight into investing in people and building high-trust relationships. He believes that excellence in both of these areas can build the best team for delivering on the needs of customers. Outside of work, Jason enjoys spending time with his wife and three amazing kids who love to play board games.