December 5, 2019 : 2 min read

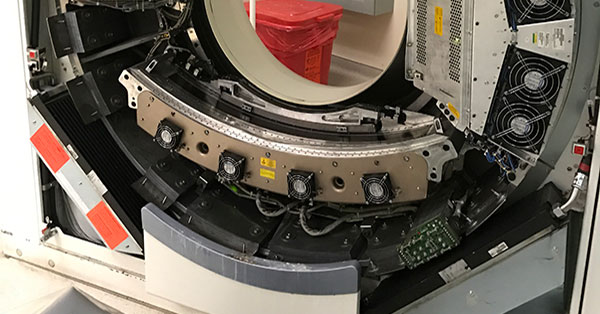

Siemens Sensation Detector Module Replacement Guide

The Siemens Sensation family has two main detector types: those found on the 10 and 16-slice systems, and those found on the 40 and 64-slice systems. Both use a proprietary, ceramic-based material to fluoresce under exposure to X-ray. They are also both comprised of 42 modules that receive the X-ray and convert it to electronic signals.

Periodically, depending on a few factors like your room temperature and humidity and your patient volume, these detector modules will begin to degrade and fail. The following are a few tips for troubleshooting detector modules and installing your replacements.

What Detector Module Failure Looks Like

A detector module problem on either type of detector usually manifests as a ring or band in axial (sequence) images or as straight lines in scouts. Swapping the suspected problem module with another is a relatively quick way to test it. If the artifact moves with the module, the module should be replaced.

If you need to replace your module(s), they can be ordered with the following part numbers:

For Siemens Sensation 10 or 16: ADM module assembly, 7273811 or ADM 6 pack (center 6), 7273852

For Siemens Sensation 40 or 64: P29F module CPL, 8428299

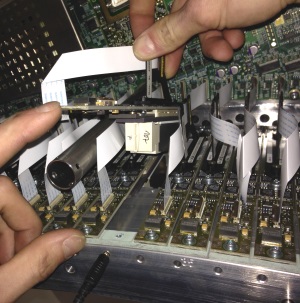

The Simple Swap

When 1 or 2 modules are posing a problem, moving them to the next-to-last detector slots can allow usable images to be acquired while a more permanent solution is considered. Slots 2 and 41 are good candidates for being temporary homes to failing modules.

The trade-off to moving a module is that it requires recreating the detector calibration tables for all techniques and slice widths. a process that takes several hours. There is also a small chance the image quality may still fail the constancy checks. However, most of the time, 1 or 2 bad modules can be moved safely.

OEM Recommendations

For the 10/16 detector, the OEM recommendation is that the center 6 detector modules be swapped out all at once as they are more closely matched in performance and spacing. The 36 remaining modules are interchangeable and can be replaced individually as needed.

For the 40/64 detector, the OEM recommendation changed a bit. They now suggest shifting failed center modules in towards center and inserting the replacement at the outer edge of the center set.

In Our Experience

Anecdotally, I’ve experienced detector module failures that appear directly related to temperature extremes. The main cause is a warm climate problem at sites that powered down their CT overnight or over weekends. During the down time the HVAC failed or building temperature was allowed to rise at night. There have also been cases where the CT was shut down too quickly after the last scan of the day.

Barring HVAC failure scenarios, it is important to allow time for the CT's cooling system to remove the heat from the last scan before powering the system down. Generally an hour or so is sufficient.

If You Need Help Now

If you're seeing artifacts in your images right now, we can help. Contact our parts department to request replacement Sensation detector modules. We carry individual modules and center 6 sets.

If the tips above aren't solving your artifact problems, we can help with on-site support as well. Contact our service department to schedule an engineer visit to your facility.

Keith Rumley

Keith Rumley is a CT Engineer at Block Imaging. He takes great pride in making sure every refurbished CT that leaves Block Imaging produces outstanding images. Since high school, he has loved all things technology and electronics (hence the career choice). Keith is happiest when he is engaged in technical problem-solving.