January 31, 2019 : 2 min read

Image Intensifier Lifespan and Signs of Failure

If you use fluoroscopy equipment like a C-arm, an R/F room, or an analog cath/angio lab you've got an image intensifier (II) that will one day need to be replaced. Most IIs have years of useful life in them, but it is not at all uncommon for a fluoroscopy system to go through at least a few IIs over the course of its life.

Because of the eventual failure of image intensifiers, we polled our service engineering team to find a few ways users can prolong the life of their II as well as some ways they'll be able to tell that an II failure is on the way. Keep reading to learn how you can help keep your II around longer as well as how you can know when to plan for a replacement.

How to Extend the Life of Your Image Intensifier

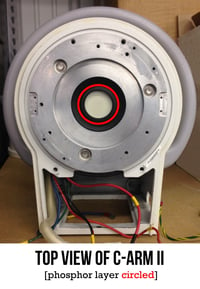

One of your II's main jobs is to intercept and convert X-ray photons into visible light.1 The layer of material

in your II that intercepts X-ray photons is called the phosphor. An II's phosphor layer can collect an unknowable, but finite amount of photons. The best way to keep your II kicking is to take a conservational approach to exposing your phosphor to X-rays.

You can reduce phosphor wear by limiting the amount of testing you do with an open field. During a test, try to block some of the rays that are coming to the phosphor with a piece of lead over the II. This will allow you to conduct your test without hitting your phosphor with a full-blast exposure.

Another way to reduce phosphor wear is to employ proper collimation techniques. Limiting your X-ray beam to the relevant areas of a given scan means that you are not needlessly exposing other areas of the phosphor layer to X-ray photons.

How to Know When Your Image Intensifier Is Failing

Aside from the X-ray photon conversion we mentioned earlier, your II's other job is to amplify the system's light signal for image brightness. When you find yourself needing to use higher technique to get the same brightness you're used to, chances are the reactivity of your phosphor is wearing down and it isn’t amplifying at the rate that it needs to.

A failing II may also begin to show sharp, dark spots in the image. These spots are caused by the breakdown of a coating inside the II's insert. This coating is part of the focal process. The spots come from areas where the coating has fallen away. Once you begin to see these, you can expect to see more of them in the near future.

When Your Image Intensifier's Time Comes

Whether by slow decline or sudden failure, every II will need replacement at some point. To prepare for this eventuality, we recommend a little advance planning. These three easy steps will help you minimize the downtime that comes with the replacement of a major component, or even get the job done during a planned break in your imaging schedule:

1. Find a parts vendor that frequently stocks the II your system uses and get your facility set up in their records. This will decrease the turnaround time on finding and ordering an II.

2. Schedule regular preventative maintenance for your system. This is a good idea for the overall health of your equipment anyway, but another set of eyes looking for warning signs of II decline will be helpful.

3. Follow up with your parts vendor. Checking in periodically with a quick email will let you know the availability of your II as well as other parts you may find yourself replacing (X-ray tube, CRT inserts, etc.).

Chris Sharrock

Chris Sharrock is the Vice President of Healthcare Solutions at Block Imaging. Each day Chris sets out to provide the best equipment, parts, and service solutions for healthcare facilities across the world. Outside of work Chris enjoys playing in a band, and spending time at the lake with his family.